What Makes Habonim’s Hydrogen Valves a Benchmark for Safety and Innovation?

In the race to decarbonise global energy systems, hydrogen has emerged as a frontrunner. Its versatility as a clean fuel – powering vehicles, heating homes, and storing renewable energy – makes it a critical pillar of the energy transition. But harnessing hydrogen safely and efficiently requires more than ambition; it demands engineering precision. That is where Habonim, a high-end manufacturer of industrial valves and actuators, steps in.

Innovation Under Pressure

Rather than adapting existing products, Habonim has taken a ground-up approach to hydrogen. “Hydrogen systems operate at ultra-high pressures, often up to 1,034 bar (15,000 psi),” explains Tzur Layish, VP of Strategy and Marketing at Habonim. “This requires valves that are not only robust and durable but also certified to the highest safety standards.”

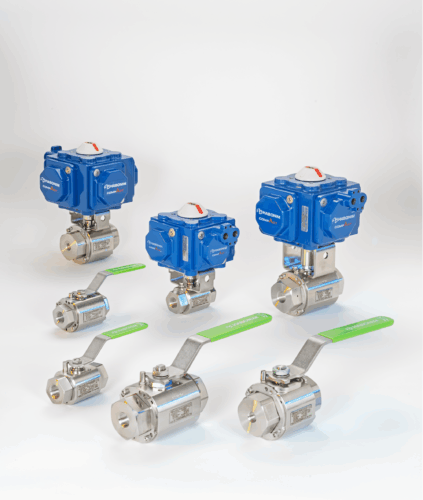

Instead of relying on conventional materials and designs, the company developed a specialised hydrogen-grade product line. The valves feature double body sealing, fire-safe designs with polymeric seals, as well as emission-proof stem sealing certified for 500,000 cycles. “These features are essential when dealing with hydrogen’s unique risks,” Tzur adds.

What sets these valves apart is not just their durability but their compliance. Habonim was the first valve manufacturer to achieve ISO 19880-3 Class A certification for hydrogen fueling stations. Their products also meet ISO 23826 for transportable pressure equipment (TPED), ATEX IIC for explosive atmospheres, and SIL 2/3 for safety in hazardous systems.

A Full-Spectrum Hydrogen Strategy

Instead of focusing on a single application, the company has mapped out the entire hydrogen value chain. “We analysed each stage – from production and storage to transportation and refueling – and developed tailored valves for every step,” says Tzur.

For hydrogen production, Habonim offers valves certified for ATEX and SIL standards. In transportation, their H24, H25 and H29 series withstand pressures up to 700 bar under TPED regulations. For refueling, they have developed two valve series compliant with ISO 19880-3 class A, supporting both H35 and H70 systems.

One standout product is the H99 series, designed specifically for ultra-high-pressure hydrogen applications. With a pressure rating of up to 1,034 bar (15,000 psi), these valves are used in fueling stations, mobile storage units, and even marine applications. “Our valves enable high flow rates, which is a huge advantage in hydrogen production and storage,” Tzur notes. “They also allow for smaller pipe diameters and simple automation with quarter-turn actuators.”

Real-World Impact and Global Reach

Across the globe, Habonim’s valves are already playing a role in pioneering hydrogen projects. One of the most notable is the H100 Fife project in Scotland – the world’s first green hydrogen heating network for homes. Powered by offshore wind, the project aims to heat up to 300 homes using 100% renewable hydrogen. “Being part of the H100 Fife project is a testament to our leadership in hydrogen technology,” says Tzur. “It’s not just about supplying valves; it’s about enabling a vision for a sustainable future.”

In China, Habonim valves are being utilised in a hydrogen supply chain project that supports the city’s expanding fleet of hydrogen-powered public transportation. This initiative is part of a larger effort to reduce urban emissions and promote clean energy public transport. Another example is in Spain, where Habonim has supplied high-Cv, high-pressure valves for a 50 MW green hydrogen production facility. These valves are critical for managing the high flow rates and pressures required in large-scale electrolysis plants. “We’re seeing a shift toward multi-megawatt hydrogen production facilities, and our valves are designed to meet those demands,” Tzur explains.

Elsewhere, Habonim has become the first company to certify an ultra-high-pressure hydrogen valve for marine use. These valves are now being deployed in hydrogen-powered vessels and Multi-Element Gas Cylinders (MEGCs), helping to decarbonise maritime transport.

Collaboration as a Core Strategy

Rather than working in isolation, Habonim maintains close partnerships with electrolyser manufacturers, EPCs, and hydrogen storage firms. “We maintain transparent communication with our partners to ensure compliance and compatibility,” Tzur explains. This collaborative approach ensures that their valves are not only technically sound but also seamlessly integrated into complex hydrogen systems.

This strategy has helped the company become a trusted supplier to leading hydrogen innovators across Europe, Asia, and North America. Habonim valves are used in applications ranging from mobility and industrial fuel switching to energy storage and marine transport.

Scaling for the Gigawatt Era

Instead of resting on its achievements, the company is preparing for the next wave of hydrogen innovation. “We are introducing a new line of welded valves for pressures between 600 and 800 bar,” reveals Tzur. “These are designed for production sites that need to store hydrogen at high pressures.”

In addition, Habonim is developing solutions to address pressure hammer effects – a common challenge in high-pressure systems – and is exploring new technologies for the liquid hydrogen market. These innovations aim at supporting the scale-up of green hydrogen projects, particularly those targeting gigawatt-scale capacities.

A Vision Rooted in Partnership

Rather than simply responding to market demand, Habonim aims to shape it. “We want to be a key partner for engineering companies and independent operators from the very beginning of their projects,” says Tzur. “This proactive approach allows us to enhance efficiency and innovation from the ground up.”

The company’s roadmap includes:

- Valves for 600-800 bar applications

- Innovative solutions for pressure hammer effects

- Special valves for the liquid hydrogen market

By aligning its R&D efforts with the evolving needs of the hydrogen economy, Habonim is positioning itself as a cornerstone of the clean energy transition.

At a time when the world is betting big on hydrogen, the need for safe, reliable, and high-performance components has never been greater. “Our goal is to support the energy transition by providing the most advanced, certified, and durable valves for hydrogen applications,” Tzur concludes. “We’re not just making valves – we’re enabling the future of clean energy.”