Ames Goldsmith, a leader in the precious metal compound industry, continues to push the boundaries of innovation with the introduction of HyPer FC150D, a new platinum catalyst designed to meet the demanding requirements of automotive PEM fuel cells. Building on a legacy of over 160 years in precious metal manufacturing, Ames Goldsmith is setting new standards for performance, durability, and cost-effectiveness in the hydrogen sector.

HyPer FC150D: A Leap Forward in Fuel Cell Catalyst Technology

HyPer FC150D is a platinum catalyst supported on a medium surface-area mesoporous carbon, designed specifically for use as a cathode catalyst in PEM fuel cells. The second generation of Ames Goldsmith’s platinum-on-carbon (Pt/C) range, this catalyst has been meticulously engineered to optimise both performance and longevity.

According to James Woodward, European Commercial Manager at Ames Goldsmith, “HyPer FC150D represents the next generation of fuel cell catalysts. We have worked hard to develop a material that not only meets but exceeds the rigorous expectations of the automotive sector. It’s all about balancing durability and performance, and we believe we’ve achieved that with this product.”

One of the key advantages of HyPer FC150D is its enhanced electrochemical surface area (ECSA), which allows for more efficient fuel cell reactions. This results in higher power output with less platinum loading, improving cost efficiency while maintaining superior performance. The carefully engineered mesoporous carbon support further enhances durability, ensuring sustained catalyst activity over prolonged operational cycles.

Initial and end-of-life performance tests conducted in-house demonstrate that HyPer FC150D maintains high activity over extended operational periods, reducing degradation typically seen in conventional Pt/C catalysts. Its optimised structure minimises particle migration and aggregation, key factors in maintaining long-term efficiency. “We have validated its performance through rigorous internal testing, and the results speak for themselves,” Woodward said. “The improvements in durability and electrochemical performance position this catalyst as a key enabler of next-generation fuel cell technology.”

Strengthening Ames Goldsmith’s HyPer Catalyst Portfolio

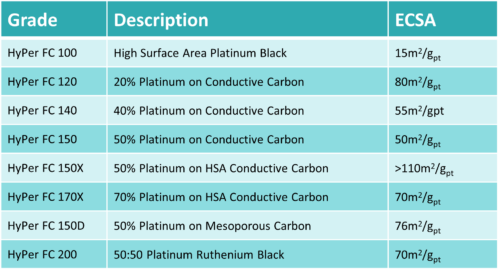

With fuel cell technologies advancing rapidly, especially in the automotive sector, this new material provides a critical enhancement to Ames Goldsmith’s existing PEM fuel cell and electrolyser catalyst offerings. The company’s portfolio includes:

- HyPer FC150X: A high-surface-area platinum catalyst offering exceptional electrochemical surface area (ECSA) for fuel cells, optimising reaction kinetics for enhanced performance.

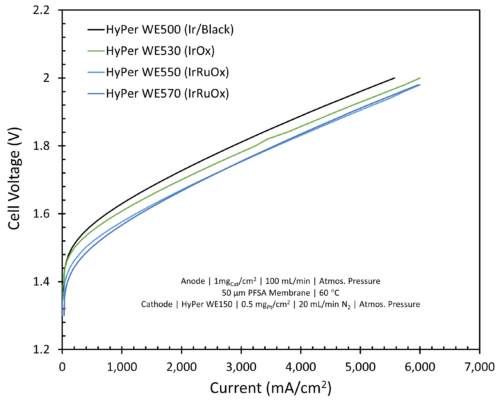

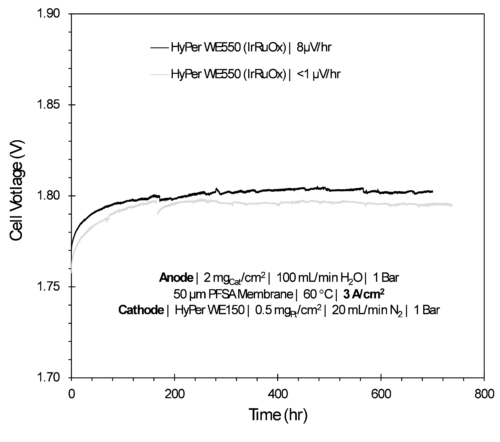

- HyPer WE550 and HyPer WE570: High-surface-area oxidised iridium-ruthenium alloy catalysts optimised for water electrolysis and PEM fuel cell applications. The HyPer 550 features 70% iridium content for maximum activity, while the HyPer 570 reduces iridium to 30%, offering a cost-effective alternative while maintaining high efficiency.

- HyPer PEMWE Range: A suite of electrolysis catalysts designed to enhance efficiency while reducing reliance on scarce precious metals. Ames Goldsmith’s low-Ir compounds offer a sustainable approach without compromising on durability or performance.

This expanded range of products highlights Ames Goldsmith’s ongoing commitment to supporting both the fuel cell and electrolyser industries with state-of-the-art materials.

Balancing Performance, Cost, and Sustainability

One of the key challenges in fuel cell development is optimising performance while minimising the use of costly precious metals. Ames Goldsmith has addressed this challenge head-on by refining its synthesis processes to maximise catalyst activity with reduced platinum and iridium loadings.

HyPer FC150D’s unique design allows manufacturers to achieve lower platinum content without sacrificing performance, addressing cost concerns in fuel cell production. This translates into reduced capital expenditure (CAPEX) for automotive and stationary fuel cell applications.

“As a company, we are focused on making hydrogen technology more economically viable,” Woodward explained. “By improving the efficiency of our catalysts and reducing the reliance on scarce resources, we are contributing to the long-term sustainability of the hydrogen industry.”

The importance of reducing iridium content, in particular, cannot be overstated. With global supply constraints and price volatility, manufacturers are seeking alternatives that maintain high performance without excessive reliance on iridium. Ames Goldsmith has already demonstrated success in scaling up low-iridium catalysts, reinforcing its position as a market leader in sustainable fuel cell and electrolyser technologies.

Ames Goldsmith’s Unique Approach to Customer Collaboration

Beyond product innovation, Ames Goldsmith’s reputation for agility and customer responsiveness sets it apart in the industry. The company prides itself on its ability to work closely with clients, tailoring solutions to specific performance and cost requirements.

“Our size allows us to be extremely agile,” Woodward said. “We respond quickly to customer needs, ensuring they receive materials that are both high-performing and cost-effective. Whether it’s a small-scale research project or a full commercial deployment, we are committed to providing the best possible support.”

This customer-centric approach has cemented Ames Goldsmith’s reputation as a trusted partner in the hydrogen sector. With manufacturing facilities strategically located across the globe, the company ensures reliable supply chains and consistent

The Future of Fuel Cell and Electrolyser Catalysts

Looking ahead, Ames Goldsmith continues to invest in research and development, exploring new synthesis routes that further enhance catalyst activity and durability. The company is particularly focused on reducing specific ion contaminants that can impact membrane longevity, a key factor in the overall performance of fuel cells and electrolysis systems.

“We are not standing still,” Woodward emphasized. “Our R&D team is constantly looking at ways to improve catalyst performance and make hydrogen technology more accessible. The launch of HyPer FC150D is just one example of our ongoing commitment to innovation.”

With global interest in hydrogen technology at an all-time high, Ames Goldsmith is well-positioned to play a crucial role in the industry’s future. The company’s expertise in precious metal chemistry, combined with its commitment to sustainability and customer collaboration, ensures that it remains at the forefront of fuel cell and electrolyser advancements.

As the hydrogen economy continues to grow, the demand for high-performance, cost-effective catalysts will only increase. Ames Goldsmith’s HyPer range, now strengthened by the introduction of HyPer FC150D, is set to make a significant impact on the industry, helping pave the way for cleaner, more efficient energy solutions worldwide. •