In 2025, German automation specialist Festo celebrates its centenary, a rare milestone for an industrial technology company. Founded in 1925 as a family-owned enterprise, Festo has grown into a global leader in factory and process automation while also shaping the future of technical education through its Festo Didactic division. Today, with more than 20,600 employees in over 60 countries, the company remains committed to innovation, reliability, and sustainability.

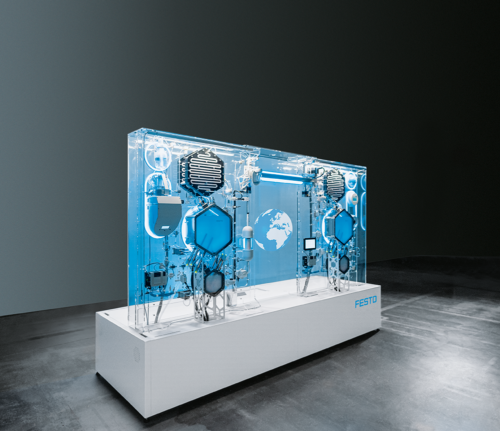

At its core, Festo specialises in pneumatic and electrical automation solutions, from drive technology and valve terminals to digital engineering tools and AI-powered maintenance systems. This dual focus allows Festo to combine the robustness of pneumatic automation with the precision of electric automation, offering efficient, scalable solutions across industries.

As industries worldwide face pressure to decarbonise and digitalise, Festo’s automation expertise is playing a pivotal role in enabling the shift to a more sustainable industrial future.

A Catalyst for Sustainable Industry

Festo defines itself as more than just a component supplier. “We see ourselves as a catalyst for a sustainable industrial future,” Alexander Vargas, Head of Global KAM and ISM Process Industries explains. Its solutions help customers reduce energy use, cut emissions, and improve efficiency.

This commitment is mirrored in Festo’s own operations. The company achieved CO₂-neutrality for Scope 1 and 2 emissions in 2024, two years ahead of schedule. Its strategy aligns with the UN Sustainable Development Goals, focusing on climate protection and resource efficiency.

Core Technologies, Pneumatics Meets Electric Automation

Festo has been at the forefront of pneumatic automation for decades, having pioneered valve terminals and modular automation concepts that are now industry standards. Pneumatics remains a cornerstone of modern industry thanks to its reliability and cost-effectiveness.

At the same time, Festo has invested heavily in electric automation, which offers precision and flexibility in high-tech manufacturing environments. The company’s strategy is to apply each technology, pneumatic or electric, where it creates the most value. This hybrid approach ensures customers gain efficient, reliable systems tailored to their specific processes.

Enabling Industry 4.0

Digitalisation is transforming industry, and Festo is helping customers adapt. Its Festo AX software uses artificial intelligence to optimise energy use, predict quality outcomes, and enable predictive maintenance based on real-time production data.

Other tools, such as digital twins, Module Type Package (MTP) integration, and engineering toolkits, streamline system design, accelerate commissioning, and enable flexible plant operations. By combining hardware, software, and services, Festo ensures manufacturers are equipped for the Industry 4.0 era.

Energy Efficiency in Practice

Energy efficiency is not just a goal but a design principle for Festo. Products like the MSE6 energy efficiency module regulate compressed air supply and detect leaks, while the OVEM vacuum generator reduces energy consumption by up to 60%.

Festo also provides TÜV-certified energy-saving services, helping manufacturers audit and repair compressed air systems, a process that can unlock savings of up to 60%.

As the world pivots to renewable energy, Festo is increasingly active in clean energy markets, especially battery manufacturing and hydrogen production.

- Battery production, Festo provides copper and zinc-free components suitable for sensitive environments.

- Hydrogen, its automation solutions cover the entire value chain, from electrolysis and compression to storage and transport, with a focus on safety, efficiency, and scalability.

The hydrogen sector in particular highlights how Festo’s expertise in safety, certification, and automation can accelerate the adoption of clean energy technologies.

Success in hydrogen projects

Festo’s components are already deployed in hydrogen projects worldwide, from pilot plants to commercial-scale facilities.

One example is a collaboration with GP Joule, where Festo supplied VTUG valve terminals and VOFC solenoid valves for hydrogen transportation trailers. These components met SIL 3 safety standards, ensuring safe and reliable transport of hydrogen.

Festo has also contributed to the automation of electrolysers from Neumann & Esser (NEA) and pressure swing adsorption (PSA) skids from Hytron, an NEA subsidiary. Here, Festo technology enabled compact containerised designs that reduced system footprints while increasing functional safety, a vital factor for scaling up hydrogen production.

In another project with Hytron in Brazil, Festo provided a combination of angle seat valves and MPA valve terminals integrated into its CPX automation platform. The addition of predictive maintenance and condition monitoring improved process reliability, reduced downtime, and optimised hydrogen purification.

“An automation concept that is perfectly matched to the electrolyser is the key to its efficient, safe, and long-term operation,” says Vargas.

Safety and Certification

Hydrogen production poses unique challenges, volatile gases, corrosive media, and high pressures. Festo addresses these with certified, media-resistant components designed for reliability. Its valves, manifolds, and seals comply with IEC 61508 (SIL) standards for functional safety and ATEX/IECEx certifications for explosive environments.

With in-house endurance and safety testing, Festo ensures that every component is robust enough for the demanding conditions of hydrogen infrastructure.

Festo invests more than 7% of its annual sales in R&D, often with a focus on emerging energy technologies.

One standout initiative is the BionicHydrogenBattery project, which uses the bacterium Thermoanaerobacter kivui to convert hydrogen and carbon dioxide into formic acid for safe, efficient storage and transport. By scaling this process from the lab to industry, Festo demonstrates how automation can unlock novel pathways for energy storage.

Education and Skills for the Hydrogen Future

Technology alone is not enough, trained people are essential. Through Festo Didactic, the company supports workforce development with training systems for renewable energy and hydrogen applications. Its Hydrogen Fuel Cell Training System gives students hands-on experience with fuel cell principles, while its “Green Skills” programmes provide industry-focused education to close the skills gap.

By combining innovation with education, Festo helps industries adopt clean technologies faster and more effectively.

Festo also works closely with system integrators, electrolyser manufacturers, and EPCs to deliver pre-configured, ready-to-install solutions, including control cabinets, valve assemblies, and complete automation packages. Acting as a single-source supplier reduces vendor complexity and simplifies logistics, while a global footprint ensures consistent engineering support and on-site service across project phases.

“As a global partner, our goal is to reduce complexity for customers, from design through to commissioning, so they can scale hydrogen faster and more safely,” notes Vargas. His role spans key account management and process-industry segment leadership at Festo, reflecting the company’s deep focus on hydrogen and other process applications.

Looking Ahead

As Festo enters its second century, its role in automation and sustainability is only expanding. The company envisions itself as a foundational partner in scaling up green hydrogen technologies and enabling the global energy transition.

“We are focused on practical solutions that help customers save energy today, while building the digital and safety backbone for tomorrow’s hydrogen economy,” adds Vargas. “That combination of reliability, efficiency, and scalability is where Festo makes the difference.”

With a century of expertise, a global footprint, and a strong commitment to sustainability, Festo is poised to remain a key enabler of industrial innovation, whether in traditional automation or in the emerging hydrogen economy.